Thehkr - 無標題

More Posts from Thehkr and Others

The Artemis Story: Where We Are Now and Where We’re Going

Using a sustainable architecture and sophisticated hardware unlike any other, the first woman and the next man will set foot on the surface of the Moon by 2024. Artemis I, the first mission of our powerful Space Launch System (SLS) rocket and Orion spacecraft, is an important step in reaching that goal.

As we close out 2019 and look forward to 2020, here’s where we stand in the Artemis story — and what to expect in 2020.

Cranking Up The Heat on Orion

The Artemis I Orion spacecraft arrived at our Plum Brook Station in Sandusky, Ohio, on Tuesday, Nov. 26 for in-space environmental testing in preparation for Artemis I.

This four-month test campaign will subject the spacecraft, consisting of its crew module and European-built service module, to the vacuum, extreme temperatures (ranging from -250° to 300° F) and electromagnetic environment it will experience during the three-week journey around the Moon and back. The goal of testing is to confirm the spacecraft’s components and systems work properly under in-space conditions, while gathering data to ensure the spacecraft is fit for all subsequent Artemis missions to the Moon and beyond. This is the final critical step before the spacecraft is ready to be joined with the Space Launch System rocket for this first test flight in 2020!

Bringing Everyone Together

On Dec. 9, we welcomed members of the public to our Michoud Assembly Facility in New Orleans for #Artemis Day and to get an up-close look at the hardware that will help power our Artemis missions. The 43-acre facility has more than enough room for guests and the Artemis I, II, and III rocket hardware! NASA Administrator Jim Bridenstine formally unveiled the fully assembled core stage of our SLS rocket for the first Artemis mission to the Moon, then guests toured of the facility to see flight hardware for Artemis II and III. The full-day event — complete with two panel discussions and an exhibit hall — marked a milestone moment as we prepare for an exciting next phase in 2020.

Rolling On and Moving Out

Once engineers and technicians at Michoud complete functional testing on the Artemis I core stage, it will be rolled out of the Michoud factory and loaded onto our Pegasus barge for a very special delivery indeed. About this time last year, our Pegasus barge crew was delivering a test version of the liquid hydrogen tank from Michoud to NASA’s Marshall Space Flight Center in Huntsville for structural testing. This season, the Pegasus team will be transporting a much larger piece of hardware — the entire core stage — on a slightly shorter journey to the agency’s nearby Stennis Space Center near Bay St. Louis, Mississippi.

Special Delivery

Why Stennis, you ask? The giant core stage will be locked and loaded into the B2 Test Stand there for the landmark Green Run test series. During the test series, the entire stage, including its extensive avionics and flight software systems, will be tested in full. The series will culminate with a hot fire of all four RS-25 engines and will certify the complex stage “go for launch.” The next time the core stage and its four engines fire as one will be on the launchpad at NASA’s Kennedy Space Center in Florida.

Already Working on Artemis II

As Orion and SLS make progress toward the pad for Artemis I, employees at NASA centers and large and small companies across America are hard at work assembling and manufacturing flight hardware for Artemis II and beyond. The second mission of SLS and Orion will be a test flight with astronauts aboard that will go around the Moon before returning home. Our work today will pave the way for a new generation of moonwalkers and Artemis explorers.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com.

Hot New Planetary System Just Dropped.

We hope you like your planetary systems extra spicy. 🔥

A new system of seven sizzling planets has been discovered using data from our retired Kepler space telescope.

Named Kepler-385, it’s part of a new catalog of planet candidates and multi-planet systems discovered using Kepler.

The discovery helps illustrate that multi-planetary systems have more circular orbits around the host star than systems with only one or two planets.

Our Kepler mission is responsible for the discovery of the most known exoplanets to date. The space telescope’s observations ended in 2018, but its data continues to paint a more detailed picture of our galaxy today.

Here are a few more things to know about Kepler-385:

All seven planets are between the size of Earth and Neptune.

Its star is 10% larger and 5% hotter than our Sun.

This system is one of over 700 that Kepler’s data has revealed.

The planets’ orbits have been represented in sound.

Now that you’ve heard a little about this planetary system, get acquainted with more exoplanets and why we want to explore them.

Make sure to follow us on Tumblr for your regular dose of space!

Take time to think, it is the source of power. Take time to read, it is the foundation of wisdom.

The Big Build: Artemis I Stacks Up

Our Space Launch System (SLS) rocket is coming together at the agency’s Kennedy Space Center in Florida this summer. Our mighty SLS rocket is set to power the Artemis I mission to send our Orion spacecraft around the Moon. But, before it heads to the Moon, NASA puts it together right here on Earth.

Read on for more on how our Moon rocket for Artemis I will come together this summer:

Get the Base

How do crews assemble a rocket and spacecraft as tall as a skyscraper? The process all starts inside the iconic Vehicle Assembly Building at Kennedy with the mobile launcher. Recognized as a Florida Space Coast landmark, the Vehicle Assembly Building, or VAB, houses special cranes, lifts, and equipment to move and connect the spaceflight hardware together. Orion and all five of the major parts of the Artemis I rocket are already at Kennedy in preparation for launch. Inside the VAB, teams carefully stack and connect the elements to the mobile launcher, which serves as a platform for assembly and, later, for fueling and launching the rocket.

Start with the boosters

Because they carry the entire weight of the rocket and spacecraft, the twin solid rocket boosters for our SLS rocket are the first elements to be stacked on the mobile launcher inside the VAB. Crews with NASA’s Exploration Ground Systems and contractor Jacobs team completed stacking the boosters in March. Each taller than the Statue of Liberty and adorned with the iconic NASA “worm” logo, the five-segment boosters flank either side of the rocket’s core stage and upper stage. At launch, each booster produces more than 3.6 million pounds of thrust in just two minutes to quickly lift the rocket and spacecraft off the pad and to space.

Bring in the core stage

In between the twin solid rocket boosters is the core stage. The stage has two huge liquid propellant tanks, computers that control the rocket’s flight, and four RS-25 engines. Weighing more than 188,000 pounds without fuel and standing 212 feet, the core stage is the largest element of the SLS rocket. To place the core stage in between the two boosters, teams will use a heavy-lift crane to raise and lower the stage into place on the mobile launcher.

On launch day, the core stage’s RS-25 engines produce more than 2 million pounds of thrust and ignite just before the boosters. Together, the boosters and engines produce 8.8 million pounds of thrust to send the SLS and Orion into orbit.

Add the Launch Vehicle Stage Adapter

Once the boosters and core stage are secured, teams add the launch vehicle stage adapter, or LVSA, to the stack. The LVSA is a cone-shaped element that connects the rocket’s core stage and Interim Cryogenic Propulsion Stage (ICPS), or upper stage. The roughly 30-foot LVSA houses and protects the RL10 engine that powers the ICPS. Once teams bolt the LVSA into place on top of the rocket, the diameter of SLS will officially change from a wide base to a more narrow point — much like a change in the shape of a pencil from eraser to point.

Lower the Interim Cryogenic Propulsion Stage into place

Next in the stacking line-up is the Interim Cryogenic Propulsion Stage or ICPS. Like the LVSA, crews will lift and bolt the ICPS into place. To help power our deep space missions and goals, our SLS rocket delivers propulsion in phases. At liftoff, the core stage and solid rocket boosters will propel Artemis I off the launch pad. Once in orbit, the ICPS and its single RL10 engine will provide nearly 25,000 pounds of thrust to send our Orion spacecraft on a precise trajectory to the Moon.

Nearly there with the Orion stage adapter

When the Orion stage adapter crowns the top of the ICPS, you’ll know we’re nearly complete with stacking SLS rocket for Artemis I. The Orion Stage Adapter is more than just a connection point. At five feet in height, the Orion stage adapter may be small, but it holds and carries several small satellites called CubeSats. After Orion separates from the SLS rocket and heads to the Moon, these shoebox-sized payloads are released into space for their own missions to conduct science and technology research vital to deep space exploration. Compared to the rest of the rocket and spacecraft, the Orion stage adapter is the smallest SLS component that’s stacked for Artemis I.

Top it off

Finally, our Orion spacecraft will be placed on top of our Moon rocket inside the VAB. The final piece will be easy to spot as teams recently added the bright red NASA “worm” logotype to the outside of the spacecraft. The Orion spacecraft is much more than just a capsule built to carry crew. It has a launch abort system, which will carry the crew to safety in case of an emergency, and a service module developed by the European Space Agency that will power and propel the spacecraft during its three-week mission. On the uncrewed Artemis I mission, Orion will check out the spacecraft’s critical systems, including navigation, communications systems, and the heat shield needed to support astronauts who will fly on Artemis II and beyond.

Ready for launch!

The path to the pad requires many steps and check lists. Before Artemis I rolls to the launch pad, teams will finalize outfitting and other important assembly work inside the VAB. Once assembled, the integrated SLS rocket and Orion will undergo several final tests and checkouts in the VAB and on the launch pad before it’s readied for launch.

The Artemis I mission is the first in a series of increasingly complex missions that will pave the way for landing the first woman and the first person of color on the Moon. The Space Launch System is the only rocket that can send NASA astronauts aboard NASA’s Orion spacecraft and supplies to the Moon in a single mission.

Make sure to follow us on Tumblr for your regular dose of space!

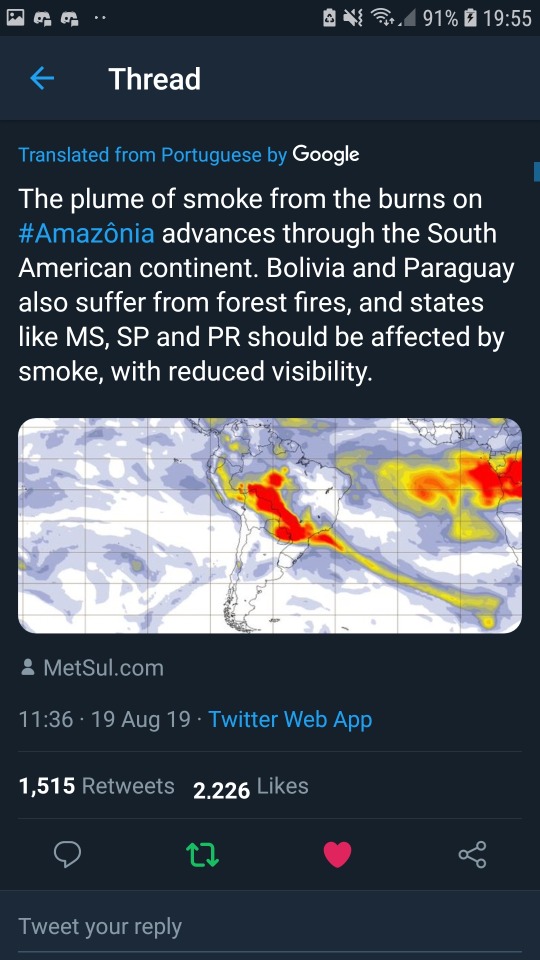

This is São Paulo at 3 PM today

No, this is not just a dark storm cloud

It's smoke

Just this year the deforestation rate of the Amazon rainforest rose more than 60%. This is a direct consequence of Jair Bolsonaro's government, treating the forest as an area of exploitation and not preservation, attempting to cease the rights of our indigenous population and straight up lying and censoring data

Our forest is dying and nobody cares

Ricardo Rodriguez - Waveloop

-

789abc123xyz liked this · 3 years ago

789abc123xyz liked this · 3 years ago -

dogteddy liked this · 3 years ago

dogteddy liked this · 3 years ago -

smile05160314 liked this · 3 years ago

smile05160314 liked this · 3 years ago -

hison5449 liked this · 3 years ago

hison5449 liked this · 3 years ago -

aka1007 liked this · 4 years ago

aka1007 liked this · 4 years ago -

ikestains liked this · 4 years ago

ikestains liked this · 4 years ago -

unlikelypaintercat liked this · 4 years ago

unlikelypaintercat liked this · 4 years ago -

ragapapah liked this · 4 years ago

ragapapah liked this · 4 years ago -

tktk21 liked this · 4 years ago

tktk21 liked this · 4 years ago -

ebrume liked this · 4 years ago

ebrume liked this · 4 years ago -

thehkr reblogged this · 4 years ago

thehkr reblogged this · 4 years ago -

thehkr liked this · 4 years ago

thehkr liked this · 4 years ago -

haruhikos liked this · 4 years ago

haruhikos liked this · 4 years ago -

spiralx liked this · 4 years ago

spiralx liked this · 4 years ago -

a0926222178 reblogged this · 4 years ago

a0926222178 reblogged this · 4 years ago