Bruna Lirio

Bruna Lirio

More Posts from Thehkr and Others

The Rover Doctor is in: The Anatomy of a NASA Human Exploration Rover Challenge Rover

Exploration and inspiration collide head-on in our Human Exploration Rover Challenge held near Marshall Space Flight Center in Huntsville, Alabama, each April. The annual competition challenges student teams from around the world to design, build and drive a human-powered rover over a punishing half-mile course with tasks and obstacles similar to what our astronauts will likely have on missions to the Moon, Mars and beyond.

The anatomy of the rover is crucial to success. Take a look at a few of the vital systems your rover will need to survive the challenge!

The Chassis

A rover’s chassis is its skeleton and serves as the framework that all of the other rover systems attach to. The design of that skeleton incorporates many factors: How will your steering and braking work? Will your drivers sit beside each other, front-to-back or will they be offset? How high should they sit? How many wheels will your rover have? All of those decisions dictate the design of your rover’s chassis.

Wheels

Speaking of wheels, what will yours look like? The Rover Challenge course features slick surfaces, soft dunes, rocky craters and steep hills – meaning your custom-designed wheels must be capable of handling diverse landscapes, just as they would on the Moon and Mars. Carefully cut wood and cardboard, hammer-formed metal and even 3-D printed polymers have all traversed the course in past competitions.

Drivetrain

You’ve got your chassis design. Your wheels are good to go. Now you have to have a system to transfer the energy from your drivers to the wheels – the drivetrain. A good drivetrain will help ensure your rover crosses the finish line under the 8-minute time limit. Teams are encouraged to innovate and think outside the traditional bike chain-based systems that are often used and often fail. Exploration of the Moon and Mars will require new, robust designs to explore their surfaces. New ratchet systems and geared drivetrains explored the Rover Challenge course in 2019.

Colors and Gear

Every good rover needs a cool look. Whether you paint it your school colors, fly your country’s flag or decorate it to support those fighting cancer (Lima High School, above, was inspired by those fighting cancer), your rover and your uniform help tell your story to all those watching and cheering you on. Have fun with it!

Are you ready to conquer the Rover Challenge course? Join us in Huntsville this spring! Rover Challenge registration is open until January 16, 2020 for teams based in the United States.

If building rovers isn’t your space jam, we have other Artemis Challenges that allow you to be a part of the NASA team – check them out here.

Want to learn about our Artemis program that will land the first woman and next man on the Moon by 2024? Go here to read about how NASA, academia and industry and international partners will use innovative technologies to explore more of the lunar surface than ever before. Through collaborations with our commercial, international and academic partners, we will establish sustainable lunar exploration by 2028, using what we learn to take astronauts to Mars.

The students competing in our Human Exploration Rover Challenge are paramount to that exploration and will play a vital role in helping NASA and all of humanity explore space like we’ve never done before!

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

Tomorrow’s Technology on the Space Station Today

Tablets, smart appliances, and other technologies that are an indispensable part of daily life are no longer state-of-the-art compared to the research and technology development going on over our heads. As we celebrate 20 years of humans continuously living and working in space aboard the International Space Station, we’re recapping some of the out-of-this-world tech development and research being done on the orbiting lab too.

Our Space Technology Mission Directorate (STMD) helps redefine state-of-the-art tech for living and working in space. Here are 10 technologies tried and tested on the space station with helping hands from its astronaut occupants over the years.

1. Astronaut Wanna-Bees

Astronauts on the space station are responsible for everything from conducting science experiments and deploying satellites to tracking inventory and cleaning. While all are necessary, the crew can delegate some jobs to the newest robotic inhabitants – Astrobees.

These cube-shaped robots can work independently or in tandem, carrying out research activities. Once they prove themselves, the bots will take on some of the more time-consuming tasks, such as monitoring the status of dozens of experiments. The three robots – named Bumble, Honey, and Queen – can operate autonomously following a programmed set of instructions or controlled remotely. Each uses cameras for navigation, fans for propulsion, and a rechargeable battery for power. The robots also have a perching arm that lets them grip handrails or hold items. These free-flying helpers take advantage of another STMD technology called Gecko Grippers that “stick” to any surface.

2. Getting a Grip in Microgravity

We wanted to develop tools for grabbing space junk, and something strong and super-sticky is necessary to collect the diverse material orbiting Earth. So, engineers studied the gecko lizard, perhaps the most efficient “grabber” on this planet. Millions of extremely fine hairs on the bottom of their feet make an incredible amount of contact with surfaces so the gecko can hold onto anything. That inspired our engineers to create a similar material.

Now the Gecko Gripper made by OnRobot is sold on the commercial market, supporting industrial activities such as materials handling and assembly. The NASA gecko adhesive gripper that’s being tested in microgravity on the Astrobee robots was fabricated on Earth. But other small plastic parts can now be manufactured in space.

3. Make It, or Don’t Take It

Frequent resupply trips from Earth to the Moon, Mars, and other solar system bodies are simply not realistic. In order to become truly Earth-independent and increase sustainability, we had to come up with ways to manufacture supplies on demand.

A demonstration of the first 3D printer in space was tested on the space station in 2014, proving it worked in microgravity. This paved the way for the first commercial 3D printer in space, which is operated by Made In Space. It has successfully produced more than 150 parts since its activation in 2016. Designs for tools, parts, and many other objects are transmitted to the station by the company, which also oversees the print jobs. Different kinds of plastic filaments use heat and pressure in a process that’s similar to the way a hot glue gun works. The molten material is precisely deposited using a back-and-forth motion until the part forms. The next logical step for efficient 3D printing was using recycled plastics to create needed objects.

4. The Nine Lives of Plastic

To help fragile technology survive launch and keep food safe for consumption, NASA employs a lot of single-use plastics. That material is a valuable resource, so we are developing a number of ways to repurpose it. The Refabricator, delivered to the station in 2018, is designed to reuse everything from plastic bags to packing foam. The waste plastic is super-heated and transformed into the feedstock for its built-in 3D printer. The filament can be used repeatedly: a 3D-printed wrench that’s no longer needed can be dropped into the machine and used to make any one of the pre-programmed objects, such as a spoon. The dorm-fridge-sized machine created by Tethers Unlimited Inc. successfully manufactured its first object, but the technology experienced some issues in the bonding process likely due to microgravity’s effect on the materials. Thus, the Refabricator continues to undergo additional testing to perfect its performance.

5. Speed Metal

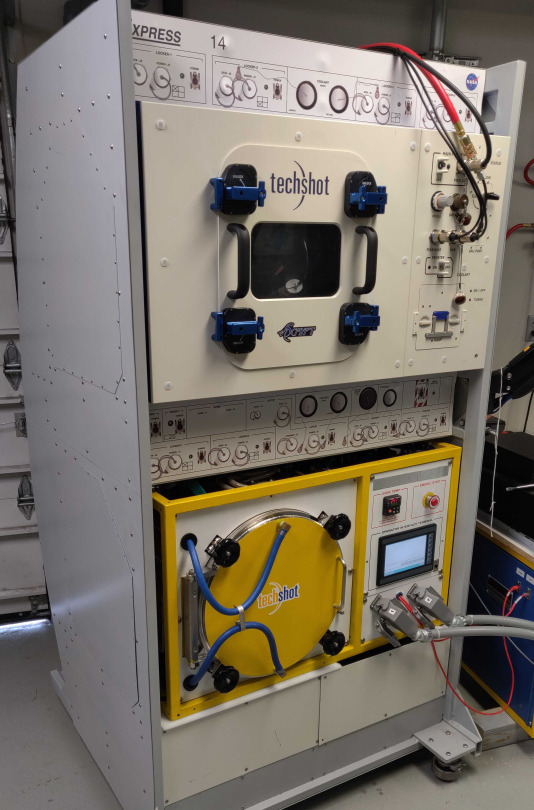

An upcoming hardware test on the station will try out a new kind of 3D printer. The on-demand digital manufacturing technology is capable of using different kinds of materials, including plastic and metals, to create new parts. We commissioned TechShot Inc. to build the hardware to fabricate objects made from aerospace-grade metals and electronics. On Earth, FabLab has already demonstrated its ability to manufacture strong, complex metal tools and other items. The unit includes a metal additive manufacturing process, furnace, and endmill for post-processing. It also has built-in monitoring for in-process inspection. When the FabLab is installed on the space station, it will be remotely operated by controllers on Earth. Right now, another printer created by the same company is doing a different kind of 3D printing on station.

6. A Doctor’s BFF

Today scientists are also learning to 3D print living tissues. However, the force of gravity on this planet makes it hard to print cells that maintain their shape. So on Earth, scientists use scaffolding to help keep the printed structures from collapsing.

The 3D BioFabrication Facility (BFF) created by TechShot Inc. could provide researchers a gamechanger that sidesteps the need to use scaffolds by bioprinting in microgravity. This first American bioprinter in space uses bio-inks that contain adult human cells along with a cell-culturing system to strengthen the tissue over time. Eventually, that means that these manufactured tissues will keep their shape once returned to Earth’s gravity! While the road to bioprinting human organs is likely still many years away, these efforts on the space station may move us closer to that much-needed capability for the more than 100,000 people on the wait list for organ transplant.

7. Growing Vitamins

Conditions in space are hard on the human body, and they also can be punishing on food. Regular deliveries of food to the space station refresh the supply of nutritious meals for astronauts. But prepackaged food stored on the Moon or sent to Mars in advance of astronauts could lose some nutritional value over time.

That’s why the BioNutrients experiment is underway. Two different strains of baker’s yeast which are engineered to produce essential nutrients on demand are being checked for shelf life in orbit. Samples of the yeast are being stored at room temperature aboard the space station and then are activated at different intervals, frozen, and returned to Earth for evaluation. These tests will allow scientists to check how long their specially-engineered microbes can be stored on the shelf, while still supplying fresh nutrients that humans need to stay healthy in space. Such microbes must be able to be stored for months, even years, to support the longer durations of exploration missions. If successful, these space-adapted organisms could also be engineered for the potential production of medicines. Similar organisms used in this system could provide fresh foods like yogurt or kefir on demand. Although designed for space, this system also could help provide nutrition for people in remote areas of our planet.

8. Rough and Ready

Everything from paints and container seals to switches and thermal protection systems must withstand the punishing environment of space. Atomic oxygen, charged-particle radiation, collisions with meteoroids and space debris, and temperature extremes (all combined with the vacuum) are just some conditions that are only found in space. Not all of these can be replicated on Earth. In 2001, we addressed this testing problem with the Materials International Space Station Experiment (MISSE). Technologists can send small samples of just about any technology or material into low-Earth orbit for six months or more. Mounted to the exterior of the space station, MISSE has tested more than 4,000 materials. More sophisticated hardware developed over time now supports automatic monitoring that sends photos and data back to researchers on Earth. Renamed the MISSE Flight Facility, this permanent external platform is now owned and operated by the small business, Alpha Space Test & Research Alliance LLC. The woman-owned company is developing two similar platforms for testing materials and technologies on the lunar surface.

9. Parachuting to Earth

Small satellites could provide a cheaper, faster way to deliver small payloads to Earth from the space station. To do just that, the Technology Education Satellite, or TechEdSat, develops the essential technologies with a series of CubeSats built by college students in partnership with NASA. In 2017, TechEdSat-6 deployed from the station, equipped with a custom-built parachute called exo-brake to see if a controlled de-orbit was possible. After popping out of the back of the CubeSat, struts and flexible cords warped the parachute like a wing to control the direction in which it travelled. The exo-brake uses atmospheric drag to steer a small satellite toward a designated landing site. The most recent mission in the series, TechEdSat-10, was deployed from the station in July with an improved version of an exo-brake. The CubeSat is actively being navigated to the target entry point in the vicinity of the NASA’s Wallops Flight Facility on Wallops Island, Virginia.

10. X-ray Vision for a Galactic Position System

Independent navigation for spacecraft in deep space is challenging because objects move rapidly and the distances between are measured in millions of miles, not the mere thousands of miles we’re used to on Earth. From a mission perched on the outside of the station, we were able to prove that X-rays from pulsars could be helpful. A number of spinning neutron stars consistently emit pulsating beams of X-rays, like the rotating beacon of a lighthouse. Because the rapid pulsations of light are extremely regular, they can provide the precise timing required to measure distances.

The Station Explorer for X-Ray Timing and Navigation (SEXTANT) demonstration conducted on the space station in 2017 successfully measured pulsar data and used navigation algorithms to locate the station as it moved in its orbit. The washing machine-sized hardware, which also produced new neutron star science via the Neutron star Interior Composition Explorer (NICER), can now be miniaturized to develop detectors and other hardware to make pulsar-based navigation available for use on future spacecraft.

As NASA continues to identify challenges and problems for upcoming deep space missions such as Artemis, human on Mars, and exploring distant moons such as Titan, STMD will continue to further technology development on the space station and Earth.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

We judge ourselves by what we feel capable of doing, while others judge us by what we have already done.

Henry Wadsworth Longfellow (via quotemadness)

イエス・キリストbotさんのツイート: “←語彙力がある人 語彙力がない人→… ”

Motivations are likely to be multifactorial and may be influenced by individual or organizational biases and competing interests.

An additional contributing factor is that individuals may be motivated to share information that they perceive to be both accurate and of social value.

Roman's primary structure hangs from cables as it moves into the big clean room at NASA's Goddard Space Flight Center.

What Makes the Clean Room So Clean?

When you picture NASA’s most important creations, you probably think of a satellite, telescope, or maybe a rover. But what about the room they’re made in? Believe it or not, the room itself where these instruments are put together—a clean room—is pretty special.

A clean room is a space that protects technology from contamination. This is especially important when sending very sensitive items into space that even small particles could interfere with.

There are two main categories of contamination that we have to keep away from our instruments. The first is particulate contamination, like dust. The second is molecular contamination, which is more like oil or grease. Both types affect a telescope’s image quality, as well as the time it takes to capture imagery. Having too many particles on our instruments is like looking through a dirty window. A clean room makes for clean science!

Two technicians clean the floor of Goddard’s big clean room.

Our Goddard Space Flight Center in Greenbelt, Maryland has the largest clean room of its kind in the world. It’s as tall as an eight-story building and as wide as two basketball courts.

Goddard’s clean room has fewer than 3,000 micron-size particles per cubic meter of air. If you lined up all those tiny particles, they’d be no longer than a sesame seed. If those particles were the size of 16-inch (0.4-meter) inflatable beach balls, we’d find only 3,000 spread throughout the whole body of Mount Everest!

A clean room technician observes a sample under a microscope.

The clean room keeps out particles larger than five microns across, just seven percent of the width of an average human hair. It does this via special filters that remove around 99.97% of particles 0.3 microns and larger from incoming air. Six fans the size of school buses spin to keep air flowing and pressurize the room. Since the pressure inside is higher, the clean air keeps unclean air out when doors open.

A technician analyzes a sample under ultraviolet light.

In addition, anyone who enters must wear a “bunny suit” to keep their body particles away from the machinery. A bunny suit covers most of the person inside. Sometimes scientists have trouble recognizing each other while in the suits, but they do get to know each other’s mannerisms very well.

This illustration depicts the anatomy of a bunny suit, which covers clean room technicians from head to toe to protect sensitive technology.

The bunny suit is only the beginning: before putting it on, team members undergo a preparation routine involving a hairnet and an air shower. Fun fact – you’re not allowed to wear products like perfume, lotion, or deodorant. Even odors can transfer easily!

Six of Goddard’s clean room technicians (left to right: Daniel DaCosta, Jill Bender, Anne Martino, Leon Bailey, Frank D’Annunzio, and Josh Thomas).

It takes a lot of specialists to run Goddard’s clean room. There are 10 people on the Contamination Control Technician Team, 30 people on the Clean Room Engineering Team to cover all Goddard missions, and another 10 people on the Facilities Team to monitor the clean room itself. They check on its temperature, humidity, and particle counts.

A technician rinses critical hardware with isopropyl alcohol and separates the particulate and isopropyl alcohol to leave the particles on a membrane for microscopic analysis.

Besides the standard mopping and vacuuming, the team uses tools such as isopropyl alcohol, acetone, wipes, swabs, white light, and ultraviolet light. Plus, they have a particle monitor that uses a laser to measure air particle count and size.

The team keeping the clean room spotless plays an integral role in the success of NASA’s missions. So, the next time you have to clean your bedroom, consider yourself lucky that the stakes aren’t so high!

Make sure to follow us on Tumblr for your regular dose of space!

-

rais007 liked this · 2 years ago

rais007 liked this · 2 years ago -

naturalamatureisbeautiful liked this · 2 years ago

naturalamatureisbeautiful liked this · 2 years ago -

gotstalook5150 reblogged this · 3 years ago

gotstalook5150 reblogged this · 3 years ago -

godheartedmanminded liked this · 4 years ago

godheartedmanminded liked this · 4 years ago -

emjayar liked this · 5 years ago

emjayar liked this · 5 years ago -

howardlll liked this · 5 years ago

howardlll liked this · 5 years ago -

differentzinecowboything liked this · 6 years ago

differentzinecowboything liked this · 6 years ago -

ariesman4fun liked this · 6 years ago

ariesman4fun liked this · 6 years ago -

imnotaflower10 liked this · 6 years ago

imnotaflower10 liked this · 6 years ago -

awesomecollectivetripin liked this · 6 years ago

awesomecollectivetripin liked this · 6 years ago -

foulfisheagleskeleton liked this · 6 years ago

foulfisheagleskeleton liked this · 6 years ago -

abrahammaslowcohen reblogged this · 6 years ago

abrahammaslowcohen reblogged this · 6 years ago -

abrahammaslowcohen liked this · 6 years ago

abrahammaslowcohen liked this · 6 years ago -

highlanders669 liked this · 6 years ago

highlanders669 liked this · 6 years ago -

importantshoefriendoaf liked this · 6 years ago

importantshoefriendoaf liked this · 6 years ago -

beautifulsfw liked this · 6 years ago

beautifulsfw liked this · 6 years ago -

elilagarto-blog liked this · 6 years ago

elilagarto-blog liked this · 6 years ago -

hoshako liked this · 6 years ago

hoshako liked this · 6 years ago -

monchito2018 reblogged this · 6 years ago

monchito2018 reblogged this · 6 years ago -

monchito2018 liked this · 6 years ago

monchito2018 liked this · 6 years ago -

pandora-excite liked this · 6 years ago

pandora-excite liked this · 6 years ago -

hiroshimacutiegirls reblogged this · 6 years ago

hiroshimacutiegirls reblogged this · 6 years ago -

xon007-blog liked this · 6 years ago

xon007-blog liked this · 6 years ago -

kenarcadiaking liked this · 6 years ago

kenarcadiaking liked this · 6 years ago -

glorioustreetheorist liked this · 6 years ago

glorioustreetheorist liked this · 6 years ago -

eclecticrascalhandsempath liked this · 6 years ago

eclecticrascalhandsempath liked this · 6 years ago -

lovelyfancytriumph liked this · 6 years ago

lovelyfancytriumph liked this · 6 years ago