La Imagen Ganadora Presentada Fue Tomada Sobre El Lago Glacial Más Grande De Islandia . El Fotógrafo

La imagen ganadora presentada fue tomada sobre el lago glacial más grande de Islandia . El fotógrafo combinó seis exposiciones para capturar no solo dos anillos de auroras verdes , sino también sus reflejos en el lago sereno. Visible en el cielo de fondo distante es la banda de nuestra Vía Láctea y la galaxia de Andrómeda .

Créditos: Stephane Vetter

More Posts from Glaretum and Others

Vía Lactea en Lake Powell

Crédito: Julio C. Lozoya

https://instagram.com/julio_c_lozoya

~Antares

Desde el sur de Francia

Crédito: Ghislain Favé

Instagram.com/ghislain_fave

Recordando al cometa NEOWISE.

Crédito: Julio C. Lozoya

Salar de Uyuni, Bolivia

Crédito: Jheison Huerta

Instagram: http://instagram.com/jheison_huerta

Web: http://jheisonhuerta.com

Senda estelar alrededor del polo norte celeste. La estrella en el centro de los arcos celestiales concentricos es Polaris.

Imagen desde Bayanhaote, en el interior de Mongolia de China.

Crédito: Jeff Dai

https://instagram.com/jeffdaiphoto

~Antares

Aurora Boreal.

Crédito: Ollie Taylor

@olliemtaylor

Tomorrow’s Technology on the Space Station Today

Tablets, smart appliances, and other technologies that are an indispensable part of daily life are no longer state-of-the-art compared to the research and technology development going on over our heads. As we celebrate 20 years of humans continuously living and working in space aboard the International Space Station, we’re recapping some of the out-of-this-world tech development and research being done on the orbiting lab too.

Our Space Technology Mission Directorate (STMD) helps redefine state-of-the-art tech for living and working in space. Here are 10 technologies tried and tested on the space station with helping hands from its astronaut occupants over the years.

1. Astronaut Wanna-Bees

Astronauts on the space station are responsible for everything from conducting science experiments and deploying satellites to tracking inventory and cleaning. While all are necessary, the crew can delegate some jobs to the newest robotic inhabitants – Astrobees.

These cube-shaped robots can work independently or in tandem, carrying out research activities. Once they prove themselves, the bots will take on some of the more time-consuming tasks, such as monitoring the status of dozens of experiments. The three robots – named Bumble, Honey, and Queen – can operate autonomously following a programmed set of instructions or controlled remotely. Each uses cameras for navigation, fans for propulsion, and a rechargeable battery for power. The robots also have a perching arm that lets them grip handrails or hold items. These free-flying helpers take advantage of another STMD technology called Gecko Grippers that “stick” to any surface.

2. Getting a Grip in Microgravity

We wanted to develop tools for grabbing space junk, and something strong and super-sticky is necessary to collect the diverse material orbiting Earth. So, engineers studied the gecko lizard, perhaps the most efficient “grabber” on this planet. Millions of extremely fine hairs on the bottom of their feet make an incredible amount of contact with surfaces so the gecko can hold onto anything. That inspired our engineers to create a similar material.

Now the Gecko Gripper made by OnRobot is sold on the commercial market, supporting industrial activities such as materials handling and assembly. The NASA gecko adhesive gripper that’s being tested in microgravity on the Astrobee robots was fabricated on Earth. But other small plastic parts can now be manufactured in space.

3. Make It, or Don’t Take It

Frequent resupply trips from Earth to the Moon, Mars, and other solar system bodies are simply not realistic. In order to become truly Earth-independent and increase sustainability, we had to come up with ways to manufacture supplies on demand.

A demonstration of the first 3D printer in space was tested on the space station in 2014, proving it worked in microgravity. This paved the way for the first commercial 3D printer in space, which is operated by Made In Space. It has successfully produced more than 150 parts since its activation in 2016. Designs for tools, parts, and many other objects are transmitted to the station by the company, which also oversees the print jobs. Different kinds of plastic filaments use heat and pressure in a process that’s similar to the way a hot glue gun works. The molten material is precisely deposited using a back-and-forth motion until the part forms. The next logical step for efficient 3D printing was using recycled plastics to create needed objects.

4. The Nine Lives of Plastic

To help fragile technology survive launch and keep food safe for consumption, NASA employs a lot of single-use plastics. That material is a valuable resource, so we are developing a number of ways to repurpose it. The Refabricator, delivered to the station in 2018, is designed to reuse everything from plastic bags to packing foam. The waste plastic is super-heated and transformed into the feedstock for its built-in 3D printer. The filament can be used repeatedly: a 3D-printed wrench that’s no longer needed can be dropped into the machine and used to make any one of the pre-programmed objects, such as a spoon. The dorm-fridge-sized machine created by Tethers Unlimited Inc. successfully manufactured its first object, but the technology experienced some issues in the bonding process likely due to microgravity’s effect on the materials. Thus, the Refabricator continues to undergo additional testing to perfect its performance.

5. Speed Metal

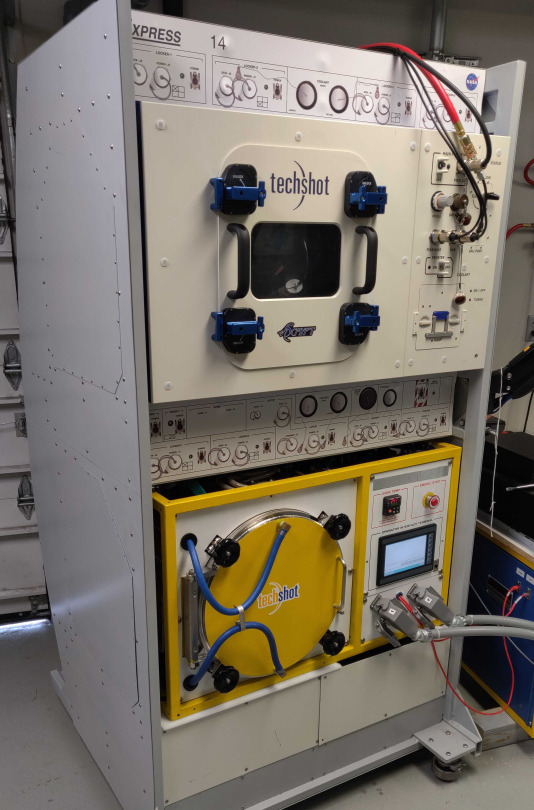

An upcoming hardware test on the station will try out a new kind of 3D printer. The on-demand digital manufacturing technology is capable of using different kinds of materials, including plastic and metals, to create new parts. We commissioned TechShot Inc. to build the hardware to fabricate objects made from aerospace-grade metals and electronics. On Earth, FabLab has already demonstrated its ability to manufacture strong, complex metal tools and other items. The unit includes a metal additive manufacturing process, furnace, and endmill for post-processing. It also has built-in monitoring for in-process inspection. When the FabLab is installed on the space station, it will be remotely operated by controllers on Earth. Right now, another printer created by the same company is doing a different kind of 3D printing on station.

6. A Doctor’s BFF

Today scientists are also learning to 3D print living tissues. However, the force of gravity on this planet makes it hard to print cells that maintain their shape. So on Earth, scientists use scaffolding to help keep the printed structures from collapsing.

The 3D BioFabrication Facility (BFF) created by TechShot Inc. could provide researchers a gamechanger that sidesteps the need to use scaffolds by bioprinting in microgravity. This first American bioprinter in space uses bio-inks that contain adult human cells along with a cell-culturing system to strengthen the tissue over time. Eventually, that means that these manufactured tissues will keep their shape once returned to Earth’s gravity! While the road to bioprinting human organs is likely still many years away, these efforts on the space station may move us closer to that much-needed capability for the more than 100,000 people on the wait list for organ transplant.

7. Growing Vitamins

Conditions in space are hard on the human body, and they also can be punishing on food. Regular deliveries of food to the space station refresh the supply of nutritious meals for astronauts. But prepackaged food stored on the Moon or sent to Mars in advance of astronauts could lose some nutritional value over time.

That’s why the BioNutrients experiment is underway. Two different strains of baker’s yeast which are engineered to produce essential nutrients on demand are being checked for shelf life in orbit. Samples of the yeast are being stored at room temperature aboard the space station and then are activated at different intervals, frozen, and returned to Earth for evaluation. These tests will allow scientists to check how long their specially-engineered microbes can be stored on the shelf, while still supplying fresh nutrients that humans need to stay healthy in space. Such microbes must be able to be stored for months, even years, to support the longer durations of exploration missions. If successful, these space-adapted organisms could also be engineered for the potential production of medicines. Similar organisms used in this system could provide fresh foods like yogurt or kefir on demand. Although designed for space, this system also could help provide nutrition for people in remote areas of our planet.

8. Rough and Ready

Everything from paints and container seals to switches and thermal protection systems must withstand the punishing environment of space. Atomic oxygen, charged-particle radiation, collisions with meteoroids and space debris, and temperature extremes (all combined with the vacuum) are just some conditions that are only found in space. Not all of these can be replicated on Earth. In 2001, we addressed this testing problem with the Materials International Space Station Experiment (MISSE). Technologists can send small samples of just about any technology or material into low-Earth orbit for six months or more. Mounted to the exterior of the space station, MISSE has tested more than 4,000 materials. More sophisticated hardware developed over time now supports automatic monitoring that sends photos and data back to researchers on Earth. Renamed the MISSE Flight Facility, this permanent external platform is now owned and operated by the small business, Alpha Space Test & Research Alliance LLC. The woman-owned company is developing two similar platforms for testing materials and technologies on the lunar surface.

9. Parachuting to Earth

Small satellites could provide a cheaper, faster way to deliver small payloads to Earth from the space station. To do just that, the Technology Education Satellite, or TechEdSat, develops the essential technologies with a series of CubeSats built by college students in partnership with NASA. In 2017, TechEdSat-6 deployed from the station, equipped with a custom-built parachute called exo-brake to see if a controlled de-orbit was possible. After popping out of the back of the CubeSat, struts and flexible cords warped the parachute like a wing to control the direction in which it travelled. The exo-brake uses atmospheric drag to steer a small satellite toward a designated landing site. The most recent mission in the series, TechEdSat-10, was deployed from the station in July with an improved version of an exo-brake. The CubeSat is actively being navigated to the target entry point in the vicinity of the NASA’s Wallops Flight Facility on Wallops Island, Virginia.

10. X-ray Vision for a Galactic Position System

Independent navigation for spacecraft in deep space is challenging because objects move rapidly and the distances between are measured in millions of miles, not the mere thousands of miles we’re used to on Earth. From a mission perched on the outside of the station, we were able to prove that X-rays from pulsars could be helpful. A number of spinning neutron stars consistently emit pulsating beams of X-rays, like the rotating beacon of a lighthouse. Because the rapid pulsations of light are extremely regular, they can provide the precise timing required to measure distances.

The Station Explorer for X-Ray Timing and Navigation (SEXTANT) demonstration conducted on the space station in 2017 successfully measured pulsar data and used navigation algorithms to locate the station as it moved in its orbit. The washing machine-sized hardware, which also produced new neutron star science via the Neutron star Interior Composition Explorer (NICER), can now be miniaturized to develop detectors and other hardware to make pulsar-based navigation available for use on future spacecraft.

As NASA continues to identify challenges and problems for upcoming deep space missions such as Artemis, human on Mars, and exploring distant moons such as Titan, STMD will continue to further technology development on the space station and Earth.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

Cometa Neowise

🗓️ Octubre 2020

📸 Tomasz Arciszewski

@arciszz

~Félicette

Parque Nacional Yellowstone

Exif:

Sony a7íii, Sony 16-35 GM, ÍOptron Skytracker Pro

Sky: 16mm, f/2.8, IS01000,120 sec. (tracked)

Foreground: 16mm, f/2.8, IS01000,300 sec. (untracked)

Crédito: Kelly Teich

https://instagram.com/kelly.teich

~Antares

-

aunque-no-te-lo-diga-te-amo reblogged this · 4 years ago

aunque-no-te-lo-diga-te-amo reblogged this · 4 years ago -

aunque-no-te-lo-diga-te-amo liked this · 4 years ago

aunque-no-te-lo-diga-te-amo liked this · 4 years ago -

concretenfells liked this · 4 years ago

concretenfells liked this · 4 years ago -

glaretum reblogged this · 4 years ago

glaretum reblogged this · 4 years ago

Glaretum fundado en el 2015 con el objetivo de divulgar la ciencia a través de la Astronomía hasta convertirnos en una fuente de conocimiento científico veraz siendo garantía de información seria y actualizada.

248 posts